All about the fourth industrial revolution: industry 4.0

We all know about the first industrial revolution. This process happened around 1760 and that meant great advances and technological transformations such as the famous steam engine. Then came the second, around 1870, which involved the massive production of electricity and the universal application of the assembly line.

The third was made to wait. It was not until 1970 that the industry went through a paradigm shift with the arrival of information technology, which would imply the appearance of automated machines and processes.

But what about the fourth revolution? When did it start? What does it consist of?

What is the origin of Industry 4.0?

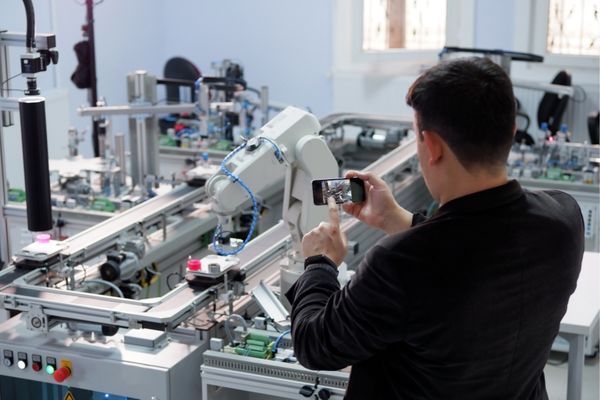

The beginning of the fourth industrial revolution is around the year 2014, when Smart factories began to emerge, in which the physical infrastructure was combined with software, sensors, and other systems that began to cooperate with each other in a flexible and global way.

Germany was the country that included this revolution in the government’s agenda as a high-tech strategy.

In our blog post on Smart factories we explain in more detail what a smart factory is and what systems it can use. You can read it by clicking here: What is a Smart Factory? Characteristics and keys to success.

What is the scope of this transformation?

The new industrial paradigm has a very broad scope, since the application of these high technologies allows numerous advantages when integrated with the processes of companies and workers.

Factories begin to function much more efficiently and with quality, as errors and risk are reduced, both for the organization and for employees.

Other opportunities could be the improvement of productivity and decision making. The more information our own workplace gives us, the easier it is for us to correct our mistakes to make better use of time, space, money, energy, or whatever resource is available.

Are we ready to face these challenges?

The advancement of high technologies is currently dizzying and very dynamic, so to put them into practice, organizations must quickly adapt to changes. This is not always easy for people since certain technologies can be complex and bring to the table the problem of the digital gap between generations.

New technologies such as artificial intelligence, the Internet of Things or augmented reality have endless applications and possibilities, but they also require a lot of learning and time to become a reality.

Read more about virtual reality and the metaverse in our latest post by clicking here: What is the metaverse? What opportunities could it offer?

At Keyplan we work on the design of industrial processes or facilities, always being aware of the continuous evolution and adaptation that industries are undergoing during this process.