Cogeneration: applications in industry

Electrical energy is essential for almost every day-to-day activity. Cogeneration makes it possible to obtain electrical energy and useful heat through the combustion of a primary energy. Having analysed the advantages of CHP, let’s see what possibilities it offers based on the needs of each sector.

Sectors and sub-sectors benefiting from cogeneration

A year ago, GENERA 2020, the International Energy and Environment Trade Fair organised by Ifema, was held, which was committed to promoting cogeneration as the main self-consumption technology in countries such as Germany, where it is already widely used, but also in Spain, due to its relevance in terms of efficiency and sustainability.

In Spain, the most developed industrial subsectors in terms of cogeneration are the paper, chemical and petrochemical, refinery, process (food, textile, wood, minerals) or construction sectors, but it has a wide potential to be implemented in fermentation, coke ovens, glass ovens, oil refining or the agricultural sector, including dairies and the sugar industry.

Similarly, cogeneration can be applied to the residential and tertiary, small and medium-sized sector, its functionality for heating or air conditioning covers all buildings in the scope of the heat distribution network: commercial (office buildings, hotels, health clubs, nursing homes); residential (flats, housing estates); institutional (schools and universities, hospitals, military bases); or municipal (district energy systems, wastewater treatment facilities, public buildings).

What is a combined heat and power plant?

With cogeneration, the energy transformation process can be used to simultaneously generate electricity and useful waste heat, utilising between 75% and 90% of the chemical energy contained in the fuel. This also implies the proximity of the generating plant and the place of consumption, which favours the autonomy of the factories and the reduction of transport costs.

Basic elements for the operation of a cogeneration plant:

– Primary energy source: the primary fuel, such as fuel oil, diesel, natural gas, biomass, etc.

– Engine or boiler: using a fossil fuel requires an engine for combustion and if gas, coal or biomass is used, a boiler where the fuel is burned.

– Mechanical energy harnessing system: the energy obtained is transferred from a shaft to a turbine or by means of a gas that circulates through pipes and moves the blades of the generator to obtain electrical energy.

– Heat recovery system: exhaust gas heat recovery boilers, dryers or heat exchangers, or even absorption units that produce cold from this low-range heat.

– Cooling system: part of the thermal energy contained in the fuel must be evacuated. Cooling towers, air condensers or heat exchangers are common in plants, as an important objective is to minimise the amount of heat released into the environment.

– Auxiliary systems: water treatment systems, pressure analysis for steam, etc., controlled by computer systems with specific software.

– Electrical system: the electrical energy produced will go directly to the user or consumer. It can pass through a power supply to treat it or through a transformer to adapt the voltage.

Types and uses of cogeneration of energy

After the production of electrical energy, cogeneration systems have three forms of thermal energy production: boiling water, steam and chilled water. Each industry and sector requires a different thermal cogeneration solution depending on its needs.

– Steam

Cogeneration with steam has a proven contribution to the reduction of greenhouse gas emissions and is an energy engine of great value due to its cost-effectiveness and safety (it is non-flammable and non-toxic). These characteristics make it a particularly suitable energy source for industries that work with chemical processes such as the alcoholic beverage sector, hospitals and the food industry.

– Hot water

Hot water cogeneration is recommended primarily for the food, pharmaceutical and chemical industries and the supply of sanitary water to residential buildings, hotels and catering services. It can be a suitable solution for other industries working with hot water circuits such as washing and dyeing processes in the textile industry.

– Chilled water

Cogeneration with chilled water is obtained in a similar way to cogeneration with hot water, the difference lies in the application of a cooling filter to obtain the former.

Of the three forms of cogeneration, it is the most widely used, being applicable in housing, hotels, commerce, sports complexes and restaurants. Its use can be extended to sectors that need continuous cooling systems, such as heavy industry, canneries or certain types of chemical industries.

Installation

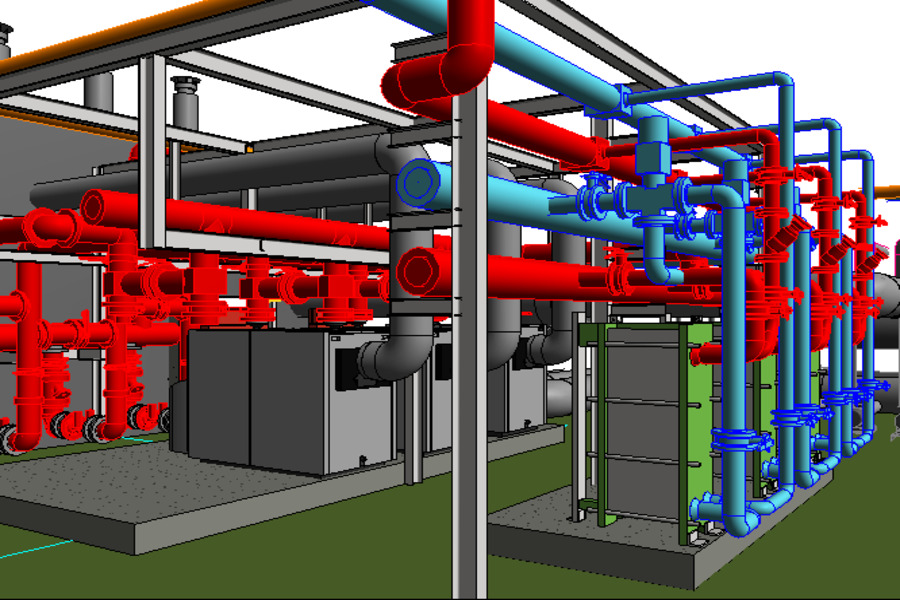

Cogeneration installations enable an efficient and pragmatic use of energy through the use of a single generator that produces heat and power in equal parts. It saves energy costs and avoids possible power outages caused by a grid failure.

Over the last 10 years, KeyPlan has become a benchmark for cogeneration projects for the Industrial and Tertiary sectors in Spain and abroad, and has the confidence of large business groups such as LOSÁN and the giant INDITEX.

In the design of customised utilisation systems, Keyplan prioritises solutions that guarantee the viability of the entire life cycle of cogeneration and trigeneration plants through the use of specific software for the needs and characteristics of the sector. Our methodology allows the determination of optimal locations for cogeneration plants and the real evaluation of resources, achieving visible economic incentives and reduction of fixed costs.

The future of energy supply systems is focused without return on the improvement of energy utilisation and sustainability techniques.